What is an MCB junction?

What is a mechanically controllable break junction and more importantly what can you do with it? The use is simple but not restricted to the following: provide alligator clips to connect to nature’s smallest available building blocks, a single atom or a single molecule. To perform an electrical measurement on one of nature’s smallest building blocks we need to attach leads to such a building block. How do you attach two leads to a single atom or a molecule? A few things are important:

- The stability of the two leads with respect to each other needs to be well below subatomic dimensions. If this boundary condition is not fulfilled vibrations will spoil our aim to perform a measurement on nature’s smallest building block.

- The two leads need to be adjustable with respect to each other to fit nature’s building block in an adjustable gap. Also, the adjustability needs to be well below subatomic dimensions to adjust a gap to exactly fit a molecule or an atom.

- The two leads will have to taper to the approximate size of the building block.

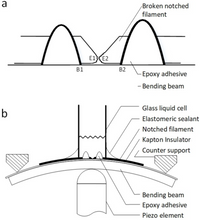

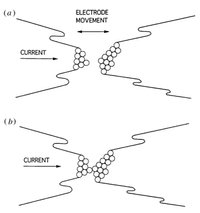

Diagram a shows the central part of the notched filament bending beam assembly with E1-B1-B2-E2 defined as the bending beam loop which has to be small in size for the proper operation of the MCB junction. Diagram b shows the assembly used to capture a single molecule between two leads.

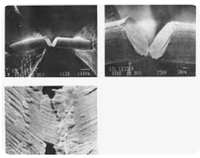

The photo shows the central section of a notched filament bending beam assembly detailing the bending beam loop of approximately 0.5 mm. For notched filament MCB's it is feasible to create bending beam loop sizes of approximately 2 to 4 times the filament diameter down to 25 micrometer filaments.

The bending beam loop, defined as E1-B1-B2-E2, must be small for two reasons. The smaller this loop is the more rigid the entire setup will be and thus the better the stability of the two electrodes after they are broken. Indeed, it can be observed in the photo that this loop measures approximately five hundred micrometers, half a millimeter! The other reason that the bending beam loop must be small is that it relates to the adjustability of the electrodes. There exists an attenuation factor between the extension of the (piezo) actuator perpendicular to the bending beam and the actual movement of the electrodes alongside the bending beam. The smaller the bending beam loop the larger this attenuation factor becomes. We would like this factor to be large as we need to adjust the electrodes to a very small, subatomic level.

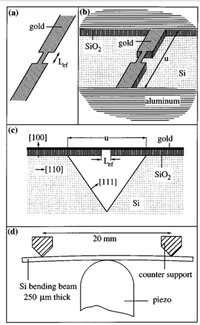

The above diagram shows the relevant features of a micro-machined MCB junction. Important here are the concentration of the elongation of u on Lef due to the rigid bridge halves. Note the small bending beam loop size of two times u. This, together with current lithography capabilities in the nm range will enable the marriage of conventional electronics (more Moore) with reproducible, reliable and repeatable molecular electronics.

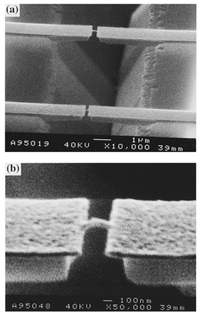

The photo displays two MCB assemblies consisting each of two bridge halves connected by a small wire where the electrodes will be formed after breaking it. The central section of this micro machined bending beam assembly details the bending beam loop size of approximately 10 micro meter.

The figure below shows the versatility as well as various regimes of the MCB junction. The electrode movement, because of the moving actuator, is alongside the bending beam. In the contact regime point contacts consisting of one atom can be studied as well as the transition to two and more atoms. Also, the transition to the vacuum regime can be investigated, where an adjustable gap exists between the electrodes. The way to capture a single molecule between the two freshly broken electrodes and to electrically isolate it from the environment is described in “Detailing the natural creation process of a single molecule MCB junction in the partially wet phase” .

The vacuum regime (a) and the contact regime (b) of the MCB junction can be studied by finetuning the force on the bending beam. In addition, the transition between these two regimes can be studied which will happen via a single atom contacted by the two electrodes/wires. Depending on the electrode material, a chain of multiple atoms can be created between the two electrodes. Platinum is for example a metal which forms a small wire several atoms long with a diameter of a single atom!